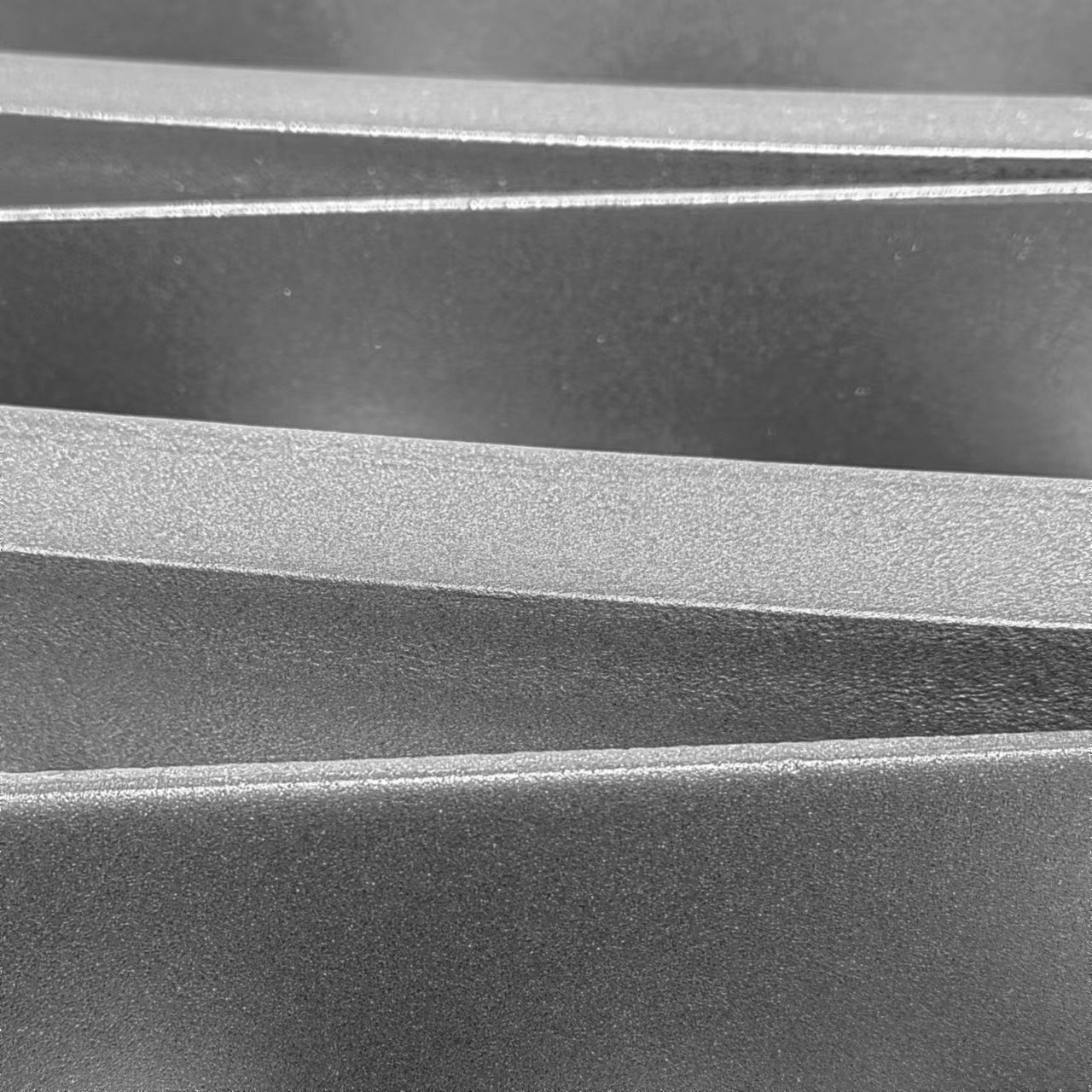

Sheet Metal Manufacturing Medium Carbon Steel Surface Sandblasting

In sheet metal manufacturing, carbon steel is one of the commonly used materials, and its surface sandblasting is a common surface treatment method. This article will introduce in detail the method, advantages and disadvantages of carbon steel surface sandblasting treatment, and its application in sheet metal manufacturing.

1. The importance of surface sandblasting:

Surface sandblasting treatment is to spray sand particles onto the surface of carbon steel to remove the surface oxide layer, dirt and burrs, improve its surface roughness, enhance coating adhesion, and improve surface quality.

2. Surface sandblasting method:

Mechanical sandblasting: Use a sandblasting machine to spray sand particles onto the surface of carbon steel at high speed to remove the surface oxide layer and dirt. Commonly used sand particles include quartz sand, glass beads, etc.

Manual sandblasting: Use a hand-held sandblasting gun to manually spray sand onto the carbon steel surface, and control the direction and intensity of the sandblasting to achieve cleaning and roughening purposes.

3. Advantages and disadvantages of surface sandblasting:

Advantages: Surface sandblasting can effectively remove the surface oxide layer and dirt, improve surface roughness, enhance coating adhesion, and improve the surface quality of carbon steel. At the same time, the construction is simple and the cost is low.

Disadvantages: Surface sandblasting may produce dust pollution, and appropriate protective measures need to be taken; at the same time, excessive sandblasting may cause surface damage and affect the appearance and performance of the product.

Summarize:

In sheet metal manufacturing, carbon steel surface sandblasting is a common surface treatment method, which can effectively improve the surface quality and coating adhesion of carbon steel products. By choosing the appropriate sandblasting method and sand particles, different surface treatment requirements can be met and the quality and competitiveness of the product can be improved.