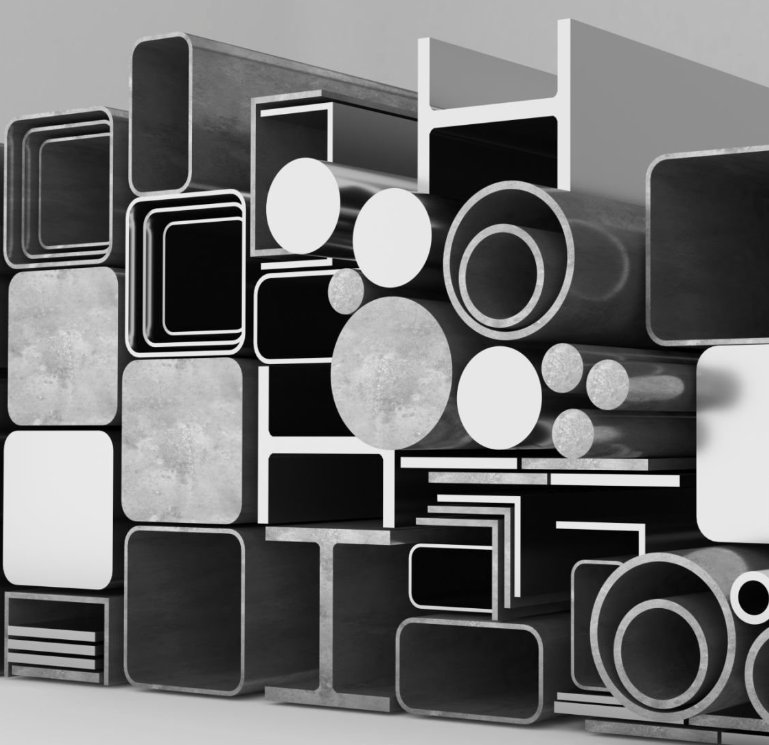

Processing difficulty of stainless steel materials in sheet metal manufacturing

In sheet metal manufacturing, the difficulty of processing stainless steel materials is an important consideration. Stainless steel has good corrosion resistance and high temperature resistance, but its high hardness, low thermal conductivity and high elastic modulus also make its processing relatively difficult. When processing stainless steel materials, sheet metal manufacturing companies need to fully understand the difficulty of processing and adopt appropriate processes and equipment to ensure product quality and production efficiency. The following will introduce in detail the processing difficulties of stainless steel materials in sheet metal manufacturing and their solutions.

1. Processing difficulty:

a. High hardness: Stainless steel material has high hardness, which makes its processing more difficult, especially for processes such as cutting, stamping and bending, which require stronger cutting force and pressure.

b. Low thermal conductivity: Stainless steel materials have poor thermal conductivity, which can easily lead to local temperature increases during processing, causing problems such as tool wear, deformation, and sticking, affecting processing quality.

c. High elastic modulus: The elastic modulus of stainless steel materials is high, which makes it prone to elastic deformation during processing, affecting processing accuracy and dimensional stability.

d. Easy to produce scratches: The surface of stainless steel materials is relatively hard, and it is easy to produce scratches and wear during processing, affecting the surface quality and aesthetics of the product.

2. Solution:

a. Select appropriate cutting tools and process parameters: Based on the high hardness and low thermal conductivity of stainless steel materials, select high-quality cutting tools and reasonably adjust process parameters such as cutting speed, feed speed, and cutting depth to improve cutting efficiency and processing. quality.

b. Use appropriate cooling lubricants: Use appropriate cooling lubricants, such as cutting fluids and lubricating oils, during processing to lower the processing temperature, reduce cutting force and frictional resistance, extend tool life, and improve processing efficiency.

c. Preheat treatment before processing: For large and thick stainless steel materials, preheat treatment can be performed before processing to reduce the hardness of the material, improve processing performance, and reduce processing difficulty.

d. Control processing temperature and stress: Control processing temperature and stress during processing to avoid overheating and overcooling, reduce thermal deformation and stress concentration of materials, and ensure processing accuracy and dimensional stability.

Summarize:

The processing difficulty of stainless steel materials is mainly reflected in its high hardness, low thermal conductivity, high elastic modulus and easy scratches. When processing stainless steel materials, sheet metal manufacturing companies need to take a series of measures, such as selecting appropriate tools and process parameters, using appropriate cooling lubricants, preheating and controlling processing temperature and stress, to overcome processing difficulties. Ensure product quality and production efficiency.